Home » Manufacturing

Manufacturing

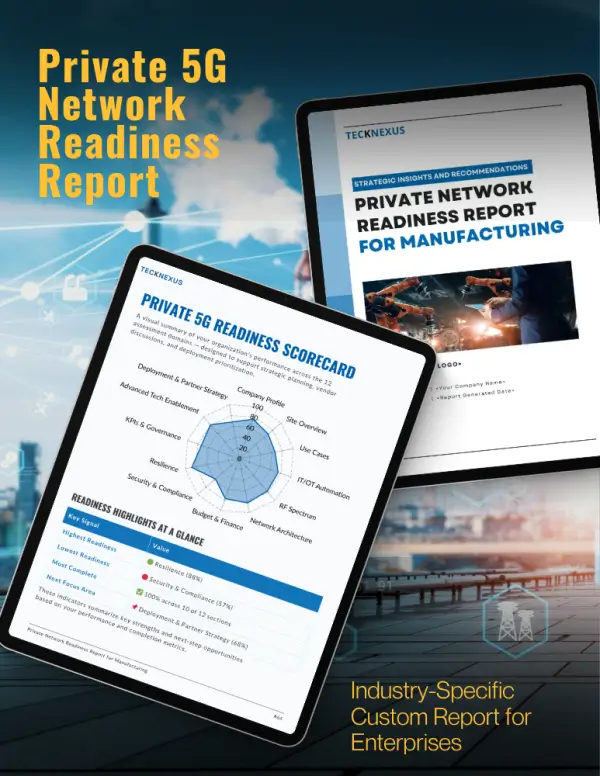

Essential insights and practical tools for navigating private networks. Get Details.

Available on Amazon & Google Books

Subscribe To Our Newsletter

- Tech News & Insight

- July 2, 2025

- Hema Kadia

- Tech News & Insight

- July 1, 2025

- 5G Americas

- Tech News & Insight

- June 27, 2025

- Hema Kadia

- Usecase

- June 23, 2025

- Hema Kadia

- Podcast

- June 22, 2025

- Hema Kadia

- Tech News & Insight

- May 29, 2025

- Hema Kadia

- Tech News & Insight

- May 12, 2025

- Hema Kadia

- Tech News & Insight

- May 12, 2025

- Hema Kadia

- Tech News & Insight

- May 9, 2025

- Rohit Nambiar

- Tech News & Insight

- May 8, 2025

- Hema Kadia

5G IN MANUFACTURING | FAQ

WHAT IS 5G IN MANUFACTURING?

5G in manufacturing refers to the application of the fifth generation of wireless communication technology in the manufacturing industry. It is a key enabler for the digital transformation of manufacturing processes, providing faster, more reliable, and low-latency connectivity compared to previous generations of wireless technology. Some of the key features of 5G that make it particularly suitable for manufacturing include:

Enhanced mobile broadband (eMBB): 5G offers significantly faster data transfer speeds (up to 100 times faster than 4G) and higher network capacity, allowing for the transfer of large amounts of data in real time.

Ultra-reliable low-latency communication (URLLC): 5G provides extremely low latency (less than 1 millisecond) and high reliability, enabling real-time control of machines and processes, which is essential for mission-critical applications in manufacturing.

Massive machine-type communication (mMTC): 5G is designed to support the connection of a vast number of devices simultaneously (up to 1 million devices per square kilometer), facilitating seamless communication between sensors, machines, and other IoT devices in a manufacturing environment.

5G in manufacturing can lead to various benefits such as:

- Improved productivity: Faster data transfer and real-time communication can enhance automation, robotics, and overall manufacturing efficiency.

- Enhanced flexibility: 5G allows for greater adaptability in production lines, enabling manufacturers to switch between products and processes more quickly and easily.

- Better monitoring and maintenance: Real-time data collection and analysis can facilitate predictive maintenance and remote monitoring, reducing downtime and maintenance costs.

- Streamlined supply chain management: Enhanced communication and data sharing can lead to more efficient logistics and inventory management, reducing lead times and costs.

- Improved worker safety: Real-time monitoring and connected wearables can help identify potential hazards and improve overall worker safety.

Overall, 5G in manufacturing can drive significant improvements in efficiency, flexibility, and productivity, paving the way for Industry 4.0 and smart manufacturing.

WHAT ARE 5G IN MANUFACTURING TOP 10 USE CASES?

Smart Manufacturing uses information and communication technologies (ICT) to manage, design, produce and monitor manufacturing processes. ICT includes a wide range of technologies such as the industrial internet of things (IIoT), cloud & edge computing, big data analytics, artificial intelligence (AI), machine learning (MI), augmented reality (AR), virtual reality, advanced robotics, digital twin, 3D printing (additive manufacturing), and of course industrial connectivity. These technologies enable the manufacturing industry’s goal of digital transformation, improving productivity, quality, safety, and reducing cost. They also help factories reach their sustainability goals by reducing waste and lowering CO₂ emissions.

The role of connectivity in the manufacturing industry is to provide a secure, reliable, and efficient communication network for data flow between machines and devices. There is a range of connectivity options for smart manufacturing. One option is to use Industrial Ethernet. Other options include WiFi or wireless technologies such as 5G or 4G/LTE, which can provide fast, reliable connections for machines and devices in harsh industrial environments.

This article examines the manufacturing industries’ use cases that take advantage of 5G as a connectivity option (predominately in a private network deployment) and one or more technologies such as artificial intelligence, advanced robotics, and augmented/virtual reality edge computing. To determine for which applications the manufacturing industry is leveraging 5G technology, the impact of 5G, and the leading players, we investigated 60 worldwide manufacturing use cases.

Production vs. Trial Use Cases: Out of the 60 use cases utilizing the 5G network, 70 percent of the use cases were already in production and 30 percent in trial mode.

Deployment Mode: Enterprises deployed a “private 5G network,” with security as the main incentive in ninety-six percent (96%) of the evaluated use cases. In comparison, enterprises chose a public-private 5G combination with network slicing for two use cases.

Leading Region & Country: Europe has the most private 5G deployments for manufacturing, with German enterprises leading the way.

Who owns Spectrum? Fifty-three percent (53%) of the enterprises used spectrum from telecommunications service providers. In comparison, forty-seven percent (47%) utilized the enterprise vertical spectrum.

1. Remote inspections, troubleshooting, and training with AR/VR

Augmented and Virtual Reality, in conjunction with 5G, can automate several operational tasks for enterprises, such as field inspections, remote assistance for troubleshooting and repair, and remote training. With 5G, you have a high bandwidth that will allow you to transmit large amounts of data quickly. The high bandwidth is important for transmitting video, images, and augmented reality content from the field to a supervisor or expert for analysis.

With augmented reality, you can overlay the information in the real world, making it easier to see what is going on. This could be used to show the location of a gas leak, for example. With Virtual Reality, you can create a virtual world that can be used for training or inspection. For example, you might build a virtual model of a plant and examine it for any issues.

Remote Inspections and Troubleshooting

Field inspections of manufacturing plants require a significant amount of technical information about the plant equipment and require considerable expertise from the field technician. Additionally, operators have a limited number of technicians who have in-depth knowledge of the plant equipment, processes, and operations for troubleshooting an issue.

With 5G technology, operators can equip the technicians with augmented reality devices to assist the field technicians with less technical expertise through an augmented display when performing maintenance and repair activities.

For example, Ericsson has been experimenting with augmented reality (AR) overlays in its Tallinn, Estonia smart factory to troubleshoot and repair electronic boards. They found that searching for information from documents, manuals, and schematics takes up roughly 50% of the total time required to troubleshoot circuit boards.

“…searching for information takes up 50% of the total time required for troubleshooting…” As a result, the typical fault detection time with AR inspection may be reduced by 15%.

There will also be fewer component replacements, resulting in energy savings and less chemical use, waste, and scrap.

Remote Training

Using immersive and interactive augmented and virtual reality-based training solutions, over 5G connectivity can give distance learning trainees the same real-world experience as if they were on-site with the trainer. It improves learning retention compared to the conventional training method.

Virtual reality can be used to help and speed up training for procedures that are impossible, difficult, or inconvenient to work with the actual equipment for example, if you want to train individuals before the equipment arrives at the site or if they are in a sterile location and don’t want people to change clothes for training. It also eliminates the cost & time for the trainers and trainees to travel to the training center & related expenses. In addition, the recorded training content can be reused for training, product assurance, compliance, and the potential redesign of solutions.

2. Asset Management: Tracking and Traceability

A range of tools and assets are utilized by technicians & engineers as a part of the overall manufacturing process. The key issues that operators face include:

- Lack of dedicated tool storage facilities

- Tools are susceptible to loss or damages, especially when being stacked one on top of another

- Tool utilization & maintenance schedules are not monitored accurately, causing costly quality issues to the final product.

- Often, technicians/engineers tend to leave tools where they’ve last been used, which in turn makes it difficult for others to find them when needed.

- Even if a central storage facility is created, it is difficult to enforce compliance in terms of returning tools to this central point after use.

The result is that a significant amount of resource time is wasted searching for and locating tools when required, which can be very unproductive in terms of loss of time and cost to the business. Asset tracking and traceability can eliminate the unproductive time spent on searching for tools. 5G capable sensors (IoT devices) can be installed on in-factory and in-transit assets (i.e., materials, tools & final products). The data from the sensors can be transmitted within the private/public 5G network, analyzed, and visualized via edge devices such as mobile handsets & centralized management systems. Tracking and traceability of assets with sensors help the manufacturing industry save time on unproductive tool location searches, reduce costs associated with outdated material disposal, and increase tool utilization.

3. Industrial automation with Automatic Guided Vehicles (AGV)

With the rise of Industry 4.0 and the Internet of Things (IoT), more and more enterprises are turning to Automatic Guided Vehicles (AGVs) to automate material transport and tasks in their smart factories. The AGV (e.g., Forklift AGVs, towing AGVs, unit load handlers, heavy burden carriers, autonomous mobile robots) is a vehicle that moves autonomously, meaning it requires no human input or control beyond the initial programming and design.

They travel along designated long lines or wires on the floor or utilize radio waves, magnets, vision cameras, geoguidance, or lasers for navigation. AGVs are used extensively in manufacturing and warehousing facilities to transport materials and products from one point to another, loading and unloading trucks or trailers, and moving stock around in the warehouse. Many smart factories use and maintain a fleet of AGVs. Still, to get the most out of them, enterprises must first digitize the manufacturing environment and connect the automobiles before capturing and combining all that data.

AGV information combined with the enterprise’s systems can capture the required data, create insights, reduce uncertainty, and support decisions. One of the key challenges with handling numerous AGVs in the manufacturing facility is connectivity. AGVs have traditionally relied on WiFi or RFID for communication between vehicles and control systems. While these technologies work well in many applications, they run into issues in busy or congested environments where multiple AGVs try to communicate with each other or with a central controller. When there are WiFi shadows in the manufacturing facility, and you lose connection with your equipment when a problem is about to happen, the gains made by investing in the AGVs can be rapidly lost.

The 5G connectivity has solved the challenge of connecting AGVs with WiFi. 5G connectivity easily scales to connect a large number of factory devices, including sensors and machines. Additionally, it provides high bandwidth, low latency, and complete coverage across the factory premises ensuring smooth operation of AGVs.

4. Industrial Automation for improving productivity

Industrial automation has revolutionized the manufacturing process. It allows for greater efficiency and precision in the production of goods. Additionally, it helps to minimize human error, which can often lead to defects in products. Automation also enables factories to operate around the clock, increasing their production capacity. The term describes a broad category of process automation that runs on industrial equipment. Control systems are often used with technologies like IoT sensors, AI vision cameras, and autonomous robots to manage repetitive tasks.

The transition to 5G connectivity will allow for broader adoption of industrial automation. For example, 5G’s low-latency wireless communications will simplify real-time machine monitoring and controls, providing industry leaders more insights into their factory operations. An industrial plant may use 5G to connect AI vision cameras along the production line to examine products and improve efficiency and productivity. Capturing real-time data from industrial equipment and production processes would allow factories to see their production patterns in much greater depth.

They can then identify the appropriate manufacturing process sequence and maximize flow by using this information, thereby reducing waste and improving production cycles. Our recent conversation with a few automobile manufacturers revealed some of the areas in which they are already using intelligent automation capabilities within their private 5G deployments:

- Cloud-based control of autonomous transport systems

- Condition monitoring for the shop floor equipment

- Augmented reality and effective communication between robotics systems and the control center

- Transfer in real-time, large quantities of test data from vehicles to the data center for more efficient data collection

- Product life cycle and process automation

- Supply chain asset management

The future of industrial manufacturing and logistics will be increasingly reliant on automation and robotics. Factories and warehouses will become smarter, with more efficient systems in place to manage the flow of goods. This will result in a more streamlined and cost-effective process, making it easier for businesses to meet consumer demand.

5. Real-time insights from field devices for decision-making

Field devices are sensors and actuators used for gathering real-time data in a manufacturing plant. They can be classified according to their functions, including measuring parameters such as temperature, pressure, flow, level, and vibration, detecting objects and controlling processes. They are an important part of the Industrial IoT infrastructure and play a critical role in gathering decision-making data. Traditionally, field devices are connected to a local area network (LAN) or the internet through industrial gateways.

As also noted for AGVs, the key difficulty is connectivity across millions of field devices throughout the manufacturing plant. Both wired and wireless connections have limitations in terms of scaling up to connect a large number of field devices, in addition to latency and interference. 5G network’s massive bandwidth, reliability, and scale to support up to one million devices per square kilometer enable enterprises to gather real-time data from the field devices across the manufacturing plant.

The data collected from the field devices is processed and analyzed for real-time insights via edge computing. This allows enterprises to make rapid decisions and take action on issues as they arise, supporting quality, safety, and efficiency in the manufacturing plant.

6. Remote Monitoring

Remote monitoring is the capability to monitor and control production assets from a remote location. This can be done through sensors that are installed in the plant or by using information technology tools to monitor the performance of the plant. Normally, operators must be physically present at the factory to monitor and control the production process and assets. But because of remote monitoring, operators do not need to be on the factory floor. They can use software systems to keep track of operations in real-time. This allows operators to find and manage assets, obtain immediate insights, and adjust the equipment to increase safety, productivity, and quality.

A use case being explored by a leading service provider is to implement a real-time video monitoring system within their dedicated private 5G network at its manufacturing plant. The private 5G network will transmit 4K Ultra HD-based live-streaming videos from numerous devices, such as cameras positioned throughout the plant. The video will be sent to a remote maintenance system, which the control center will utilize to conduct site inspections. This will eliminate the need for technicians to visit remote areas and enable early detection of failures, increasing productivity, efficiency, and safety at the plant.

In another use case, a leading supplier of power and automation products is exploring the remote monitoring of its manufacturing facilities which operate 24/7 and require continuous monitoring. The remote monitoring and control of different processes would enable them to improve security, efficiency, and quality aspects. The 5G network’s guaranteed level of service makes it perfect for time-critical remote monitoring and control operations from a centralized command center. This makes it an ideal solution for manufacturing companies that need to keep track of their production line process and ensure that everything is running smoothly.

7. Predictive and Preventive Maintenance

Predictive maintenance is the anticipation of problems that might occur in a machine or system. In predictive maintenance, arrays of sensors (IoT devices) periodically collect data on the performance of machines in a smart factory. This data is analyzed to identify any patterns that could suggest a machine is about to fail. This way, maintenance can be scheduled before a machine actually fails, preventing any unexpected downtime.

Preventive maintenance is the implementation of a plan to address those potential problems before they have a chance to cause any damage or failure. It is a critical process that helps ensure the quality and safety of the manufactured products. By conducting preventive maintenance on a regular schedule, manufacturers can catch any potential problems with the equipment before they cause any serious issues.

Additionally, preventive maintenance can help extend the life of the equipment, saving the manufacturer money in the long run. 5G connectivity will improve predictive maintenance capabilities since it provides the required high bandwidth, low latency, high reliability, and scale to collect more real-time data from a wider range of devices that monitor the equipment in the manufacturing plants.

The use of artificial intelligence (AI)-based models and analytics in conjunction with edge computing can help to identify trends and patterns in the data that can be used to make predictions about future failures. The high bandwidth, ultra-reliability, and low latency of 5G networks can help to ensure that data is processed quickly and accurately and also enable remote maintenance.

Our recent conversation with an electronics manufacturer revealed how 5G enables predictive and preventive maintenance and helps them to provide reliable and secure information to their customers in real-time. The 5G network enables real-time machine vision inspections from the start to guarantee the welding quality and the presence of components on its manufacturing lines. In addition, they train algorithms to minimize errors and readjust machines, as required.

They are using 5G technology to regulate the production environment. In particular, it’s being utilized in the controlled manufacture of electronic cards for the aviation sector, where temperature and hydrometric control is necessary to prevent damage. Enterprises can also realize cost savings through the implementation of 5G and IIoT, which allows for continual equipment monitoring. For example, instead of replacing a machine part every few months, the factory can monitor its status and replace it only when necessary.

8. Supply Chain Management

Supply chain management is the process of planning, organizing, and managing the flow of materials and products from supplier to customer. It involves the coordination of activities across a number of different businesses and functions, such as procurement, production, transportation, and distribution. In the context of manufacturing plants, supply chain management is essential for ensuring that the right materials are available at the right time and in the right quantities. It also helps to optimize the production process by minimizing waste and maximizing efficiency.

Today, many supply chain operations are labor-intensive and require a lot of human involvement at many touchpoints (for example, logging when the material arrives, physically transferring pallets, etc.) In this case, there is clearly a need for a network to provide coverage and capacity in the supply chain in order to get near real-time visibility of the whereabouts of products in transit for optimizing the operations.

A 5G network can provide the required bandwidth, low latency, and high reliability that is necessary to support such a requirement. It can also help to reduce the amount of time that is required for data transfer between manufacturing plants and their suppliers, which can be crucial for supply chain management.

For example, if a supplier is running late on a shipment, the plant will be able to notify other suppliers and make the necessary adjustments quickly. Having 5G connectivity integrated into factory equipment will enable fast, automatic replenishment of components and supplies, minimizing delays and increasing productivity as transparency into the supply chain increases.

In short, 5G connectivity can help enterprises with their goal of creating agile supply chains that can adapt to consumer demand while minimizing costs and lead times. The 5G network’s guaranteed level of service makes it perfect for time-critical remote monitoring and control operations from a centralized command center. This makes it an ideal solution for manufacturing companies that need to keep track of their production line process and ensure that everything is running smoothly.

9. Security

One of the key security challenges of manufacturing plants is the potential for cyberattacks. These attacks can cause serious damage to plant equipment and disrupt the production process. In addition, manufacturing plants are also vulnerable to physical attacks, such as theft or vandalism. Manufacturing plants also need to be aware of the possibility of industrial espionage. Corporate spies can steal confidential information about new products or manufacturing processes, which can give their company a competitive edge.

Private 5G/LTE deployments offer manufacturers a way to address some of the security challenges. By deploying a private 5G/LTE network and necessary endpoint security on the factory devices, manufacturers can limit the access to their network and control who has access to their infrastructure. They can detect and defend against threats in the dedicated private 5G network, authenticate the devices trying to connect to the network, and block unauthorized communication in real-time. Additionally, 5G’s can provide a high-quality, real-time video feed for surveillance.

10. Flexible & modular factory

A modular or flexible smart factory is a manufacturing plant where the production process can be easily reconfigured to produce different products. The factory layout can be changed, and new machines and equipment can be added without affecting the rest of the factory. This type of factory is becoming increasingly popular because it allows companies to respond quickly to changes in demand for different products. Instead of closing down the factory and rebuilding it when there is a change in demand, they can just reconfigure the production process.

The flexibility of a modular smart factory also allows companies to produce products in small batches, which is becoming more important as consumers demand more variety in the products they buy. The 5G wireless connectivity can assist with flexible or modular factories by delivering massive bandwidth, low latency, reliable coverage, and scale to connect all industrial devices. In addition, it will provide enterprises with the ability to replace their existing fixed ethernet connections with 5G connectivity, allowing for greater flexibility in production line adjustments and lower initial site investment due to lower cabling expenses.

Whitepaper

Whitepaper

Article & Insights

Download Magazine

Subscribe To Our Newsletter

Executive Interviews

Brand Connect

Amplify Your Brand & Boost Your Business

- Thought-Leadership Management

- Magazine Article

- Executive Interviews

- Whitepapers

- Research Reports

- Custom Research

- Blog Series

- Webinars

- Podcasts

- Advertorials

- Display Ads

- Event Partnership