5G Manufacturing: From Pilots to Production in the U.S.

Manufacturers and wireless providers are shifting 5G from promising pilots to scaled, revenue‑relevant deployments across American factories.

Why Now: 5G + AI + Edge for Factory Floors

A joint report from the National Association of Manufacturers (NAM) and CTIA underscores a clear inflection point: commercial 5G, industrial AI and edge computing are maturing together. Manufacturers are already applying AI broadly and expect investment to rise, and 5G provides the low latency, reliability and capacity to move high‑fidelity data between machines, sensors, and analytics stacks in real time. With 3GPP Release 16/17 capabilities such as URLLC, time‑sensitive networking integration, network slicing and non‑public networks, 5G is increasingly able to support time‑critical control, quality inspection and safety systems at scale.

Results: Safer Operations, Higher Quality, More Throughput

Production use cases are expanding and delivering measurable benefits. VictoryXR and Taqtile are using 5G to power AR training that reduces errors and accelerates upskilling while improving safety. Seegrid’s autonomous mobile robots ferry parts across Whirlpool facilities over reliable 5G links, freeing people for higher‑value work and reducing material‑handling incidents. Hitachi is applying high‑definition video and machine learning over 5G for sub‑millimeter defect detection, improving first‑pass yield. Cummins is combining secure 5G with robotics, AR/VR and sensor networks to safeguard intellectual property and optimize line operations. At Newport News Shipbuilding, a Verizon private 5G network supports AR/VR for design and training, enhances yard security, and lays a foundation for autonomous systems—critical for a defense environment with sensitive data.

Near‑Term 5G Economic Impact on Manufacturing

Independent analysis indicates 5G networks will add substantial GDP and jobs in the U.S. this decade, with manufacturing a primary beneficiary. The message is consistent: companies that operationalize 5G alongside AI and automation will capture disproportionate productivity and resiliency advantages.

5G Manufacturing Architecture: Private Networks, Edge, Security

Leaders are coalescing around repeatable designs that align spectrum, private networks, edge, and security.

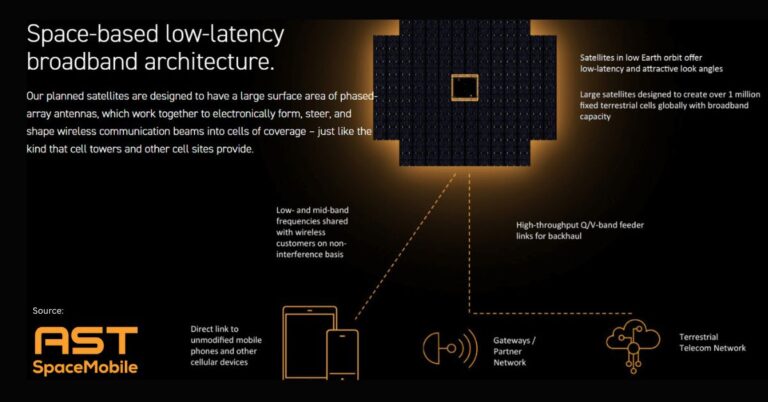

Private 5G Options and Spectrum Strategy

Manufacturers are adopting non‑public networks for deterministic performance and control. In the U.S., options span licensed mid‑band for robust coverage and interference protection, CBRS for site‑specific flexibility, and hybrid models that blend public and private with roaming. The NAM–CTIA report emphasizes the need for a sustained pipeline of licensed mid‑band to support industrial growth. For solution architects, that translates into spectrum planning early in the roadmap, including site RF design, device certification, and fallback for mission‑critical workloads.

Edge Computing with AI for 5G Factories

Most factory AI workloads are bandwidth‑intensive and latency‑sensitive, making local edge inference a default design choice. Successful deployments pair 5G user plane functions with on‑prem GPUs/CPUs to process video inspection, predictive maintenance, digital twins, and closed‑loop control. Standards‑based capabilities like TSN over 5G help coordinate with industrial Ethernet domains. The integration blueprint should include data pipelines (ingest, labeling, drift monitoring), MLOps, and zero‑trust networking to connect operations technology with IT securely.

Integrating 5G Devices, AMRs and AR/VR

Device diversity drives network design. AMRs need seamless mobility and handovers; AR/VR headsets require stable throughput and low jitter; sensors and wearables benefit from RedCap and power‑efficient profiles. Coordinate device roadmaps with 5G SA features (QoS profiles, slice assignment, positioning) and ensure certification across chosen bands. Early device testing in live RF conditions pays off by de‑risking scale.

5G Spectrum Policy for U.S. Manufacturing Competitiveness

The report’s policy takeaway is straightforward: spectrum availability will shape America’s industrial competitiveness.

Mid‑Band Spectrum: The Backbone of Industrial 5G

Mid‑band offers the best balance of capacity and coverage for factories and shipyards. CTIA and NAM call for additional allocations to meet rising industrial data demands, alongside predictable licensing frameworks that encourage long‑term investment. For enterprises, this means engaging carriers and integrators now on spectrum roadmaps and device readiness, and evaluating how public network capabilities, private licensing, and shared models fit site by site.

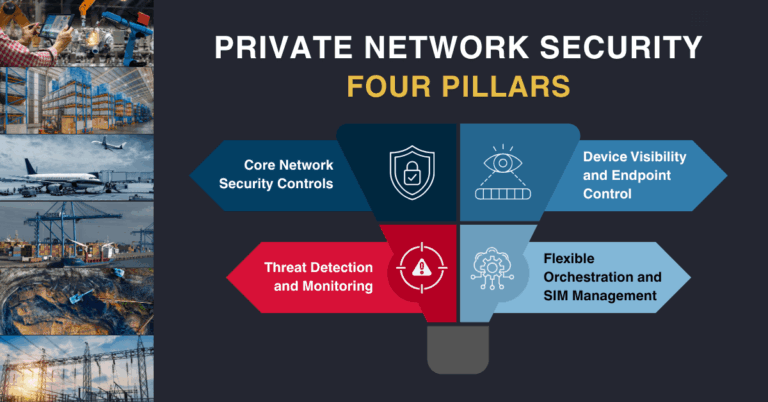

5G Security, Compliance and IP Safeguards

Private 5G’s isolation, deterministic updates, and SIM‑based identity strengthen cyber posture for sensitive environments. Manufacturers handling export‑controlled or classified work—like Newport News Shipbuilding—are treating 5G as part of a defense‑grade architecture with strong segmentation, supply‑chain security, and continuous patching. Align 5G deployments with NIST CSF/800‑53 and sector‑specific requirements, and instrument them with unified observability to satisfy audits.

Next Steps to Scale 5G in Manufacturing

Winning programs start with clear business value, rigorous integration, and a spectrum‑aware scale strategy.

Prioritize High‑ROI 5G Manufacturing Use Cases

Focus on problems with short payback and clear KPIs: vision‑based quality inspection, AMR fleet orchestration, connected worker safety, and predictive maintenance. Use reference examples from Cummins, Hitachi, Whirlpool and shipbuilding to anchor business cases, then phase expansion to more complex closed‑loop control as capabilities mature.

Create an OT/IT/Network Integration Blueprint

Stand up a joint OT/IT/Network team, select partners with 3GPP Rel‑16/17 and industrial controls expertise, and define a landing zone that includes private core, MEC, identity, and data governance. Require carrier and vendor commitments on spectrum bands, device certification, and SLAs for latency, availability, and security updates.

Design 5G for Scale, Resilience and QoS

Adopt zero‑trust principles, implement network slicing or QoS tiers by use case, and plan redundancy across power, backhaul and edge clusters. Standardize telemetry across robots, cameras, PLCs and networks, and tie outcomes to OEE, scrap rate, safety incidents and mean time to repair. Treat spectrum policy and device roadmaps as ongoing risks to manage, not one‑time decisions.

Track the 5G Manufacturing Ecosystem

Track developments from carriers, infrastructure providers and industrial platforms—examples include solutions from Verizon at Newport News Shipbuilding and broader deployments involving General Motors, Rockwell Automation, Ericsson and Samsung. As AI models evolve and devices add native 5G features, expect faster cycles from pilot to scaled value.

The bottom line: 5G is becoming core infrastructure for Manufacturing 4.0, and companies that combine it with AI, edge and disciplined integration are widening their competitive lead.