Transforming Industry 4.0 with AI and Sensor Fusion

Nokia has introduced MX Context, a new AI-powered sensor fusion solution designed to integrate multi-modal IoT data streams into a unified platform. Working alongside private 4G/5G networks, MX Context enables enterprises to achieve real-time situational awareness, eliminate data silos, and automate industrial operations more effectively.

AI-Powered Sensor Fusion: How MX Context Enhances Industrial Automation

MX Context integrates with Nokia’s industrial edge computing portfolio, including:

- Edge Compute solutions like MXIE for real-time data processing.

- MX Grid, a far-edge compute hardware platform that extends computing power closer to industrial operations.

- MXIE Data Lake, which stores structured and unstructured sensor data for historical analysis and AI training.

- MX Workmate, a generative AI assistant that enables human-machine collaboration with natural language interactions.

By ingesting data from IoT devices, industrial sensors, and private wireless networks, MX Context processes AI-driven insights that help businesses optimize assets, improve worker safety, and enhance overall operational efficiency.

Breaking Down Data Silos with AI and IoT Integration

Modern industrial facilities rely on a wide range of IoT sensors and tracking systems. However, these data streams are often siloed, limiting their usefulness. MX Context breaks down these silos by fusing data from multiple sources, including:

- GNSS and RFID tracking solutions like HERE HD GNSS and Nordic ID.

- Worker-worn sensors, including gyroscopes, accelerometers, and microphones in industrial handhelds.

- Computer vision systems, such as Nokia’s Visual Position and Object Detection (VPOD).

By combining these data sources, MX Context enables enterprises to cross-check information, improve real-time decision-making, and automate industrial workflows.

AI-Driven Industrial Automation: Key Use Cases of MX Context

1. Optimizing Industrial Asset Tracking with AI and Sensor Fusion

MX Context enhances industrial tracking and positioning by leveraging a mix of:

- Bluetooth Angle-of-Arrival (Nokia HAIP) for high-accuracy indoor positioning.

- GPS and GNSS-based tracking for outdoor location monitoring.

- Video-based tracking (VPOD) to analyze movement patterns and object detection.

This combination ensures seamless tracking continuity across industrial facilities, warehouses, and logistics centers, optimizing inventory management, process automation, and material flow.

2. Enhancing Worker Safety with AI-Powered Hazard Detection

The worker safety suite within MX Context leverages sensor fusion to detect potential hazards and trigger automated alerts. For example:

- A computer vision system detects a worker slipping or falling.

- An accelerometer in the worker’s device confirms the impact.

- AI analyzes the incident and sends real-time alerts to emergency responders.

By integrating AI-based processing, Nokia’s MX Context enables proactive workplace safety measures, helping industries reduce injuries and accidents.

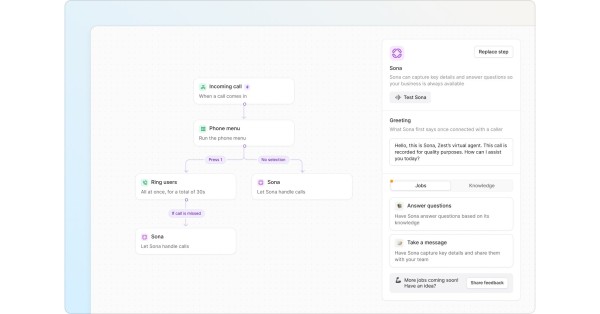

Low-Code AI Tools: Simplifying Industrial Automation

Nokia is also introducing a low-code visual development tool, allowing industrial engineers to:

- Create custom automation workflows with minimal programming knowledge.

- Design interactive dashboards for real-time monitoring and insights.

- Rapidly deploy AI-powered solutions tailored to specific industrial use cases.

This approach accelerates industrial digitalization, enabling businesses to adapt sensor fusion capabilities to their unique needs.

AI-Enabled Industrial Routers: Strengthening Real-Time Insights

To further enhance contextual awareness, Nokia is launching new industrial routers equipped with:

- Built-in sensors, including accelerometers, gyroscopes, voltmeters, and environmental sensors.

- Advanced GNSS chips for high-accuracy outdoor positioning.

These routers act as intelligent data hubs, strengthening AI-based automation and improving real-time machine insights in industrial environments.

Sensor Fusion & Industry 4.0: Driving Efficiency and Safety

According to MarketsandMarkets, the global sensor fusion market is projected to grow at a CAGR of 17.8%, reaching $18 billion by 2028. This reflects the increasing demand for solutions that unify IoT sensor data to enhance automation, efficiency, and safety.

As AI and private wireless networks continue to transform Industry 4.0, Nokia’s MX Context positions itself as a market-first solution that combines sensor fusion, AI inference, and private 5G to enable intelligent automation.

Industry Experts on Nokia MX Context

Ryan Martin, ABI Research- “Sensor fusion and AI are key capabilities for core industrial automation applications such as robotics, autonomous work cells, and human-machine collaboration. Nokia, with its private wireless and on-premise industrial edge compute, is well positioned to offer critical use cases for worker safety and tracking and positioning, bringing the power of AI insights to industrial digitalization.”

Stephan Litjens, Nokia – “AI is becoming a strategic element for Industry 4.0 transformation. Nokia’s on-premise compute capabilities offer innovative AI solutions that are OT-compliant and bring the contextual awareness needed for industrial use cases. MX Context harmonizes real-time sensor data and transforms it into actionable insights and intelligent automation.”

The Next Wave: AI’s Role in Industrial Automation

With MX Context, Nokia is redefining industrial automation by merging sensor fusion, AI, and private wireless connectivity. As AI-driven automation becomes an industry standard, enterprises leveraging MX Context will gain a competitive edge in operational efficiency, safety, and decision-making.