Introduction: Private 5G in South Korea

In April 2019, South Korea claimed the global spotlight by launching the world’s first commercial 5G service. Six years later, over 60% of its 69 million mobile subscribers use 5G. Yet, if you ask the average Korean on the street whether 5G has changed their life, you might get a shrug.

As Prof. Seong-Lyun Kim (Eric) points out, the real revolution isn’t in consumer smartphones. It’s in how factories, robots, cameras, and AI systems use 5G to transform industrial operations.

In this deep dive, Eric, CEO of Yberg, Inc. and Professor at Yonsei University, joins Hema Kadia (TeckNexus) and Mika Skarp (Cumucore) to unpack why Korea’s factories are at a turning point for private mobile networks — and what lessons the world can learn.

1) Why is Private 5G in South Korea now the tipping point for Korean factories to embrace private mobile networks?

South Korea made headlines in 2019 as the first country to switch on nationwide 5G service, nearly 6 years ahead of many peers. Over 60% of Korea’s 69 million mobile subscriptions are now on 5G plans, and the country enjoys over 90% national 5G base station coverage. On paper, that’s a perfect testbed for industrial innovation.

But as Prof. Kim candidly explains, this first wave mostly benefited consumer mobility, not advanced enterprise use cases:

“People on the street don’t feel a big difference between 4G LTE and 5G — except maybe higher bills. The real difference is meant for factories and smart systems that need speed and ultra-low latency.”

For vertical sectors like manufacturing, the game-changer isn’t just faster downloads — it’s dedicated performance guarantees, robust uplink, and seamless mobility for robots, HD sensors, and autonomous systems. Realizing this, the Korean government released a dedicated mid-band spectrum (4.7 GHz, 100 MHz) just for industrial private networks. This mirrors successful models in Germany and Japan.

Eric also highlighted an overlooked lesson: Korea’s famous 28 GHz millimeter wave demos during the 2018 Winter Olympics showed technical promise but were never commercialized at scale.

“We thought mmWave would lead the world. But operators saw the cost and decided NSA was enough. So now, for factories, we focus on what works: mid-band SA private networks.”

2) How do company size and wireless maturity shape private network planning?

Whether you’re a small contract manufacturer or a giant chaebol with 20 sites, the private 5G journey looks very different.

Cost is the first filter. Eric shared that whenever his team pitches private 5G to factory owners, the conversation always starts with the same question:

“Is it better than Wi-Fi? Okay, but how much more expensive is it?”

Small and mid-sized enterprises (SMEs) are particularly budget-conscious. They often lack deep wireless or IT teams, so they need solutions that are simple to install, simple to run, and resilient enough to “just work” with minimal support.

By contrast, large Korean conglomerates can afford dedicated staff to handle complex optimizations, like tuning handovers, managing slices, or orchestrating edge computing. They also think long-term, factoring automation ROI into broader digital transformation plans.

This creates a clear mandate for vendors:

- Flexible pricing: To compete with Wi-Fi’s cost advantage.

- Autonomous operation: Systems that self-tune and self-heal.

- Scalability: Easy to roll out from pilot line to entire factory campus.

3) Which Private 5G use cases are leading the charge in South Korean factories?

Eric didn’t stop at theory; he shared live demos from his lab and field trials. These bring the “private 5G promise” to life:

Autonomous Robots (AMRs & AGVs)

At a major pharmaceutical warehouse in Korea, Eric’s team mounted small 5G cells on the ceiling to cover robot routes. The robot loads packages, calls an elevator, rides between floors, and stays connected throughout, even inside the metal lift.

“Wi-Fi cannot do this easily. Handovers are too weak, signal drops break robot operation. 5G solves this with stable cellular links.”

Vision-Based Quality & Process Automation

In another testbed, a robot barista uses a high-definition camera to mimic human coffee brewing. Every drip, stir, and pour is controlled by a local AI model that monitors vision feeds in real-time. The high uplink data stream from the camera would choke normal Wi-Fi.

“Vision systems need stable uplink — 5G handles that. It’s not about download speed alone.”

Physical AI with LLM Integration

Taking it a step further, Eric’s latest robot barista takes complex spoken orders using an on-device small language model (SLM). For more complicated conversations, it offloads to a large cloud-based LLM. Private 5G links the edge and cloud seamlessly so the robot knows exactly what to do.

“This shows the future: physical robots with AI brains talking to customers. For that, you need fast, secure uplink and edge-to-cloud handoffs.”

Other Applications:

Factories are also investing in:

- Predictive maintenance and real-time telemetry.

- Digital twins for process optimization.

- AR/VR tools for worker training and remote troubleshooting.

- Wearable sensors for worker safety alerts.

- Asset tracking and inventory integration.

Each use case intensifies the demand for robust wireless infrastructure.

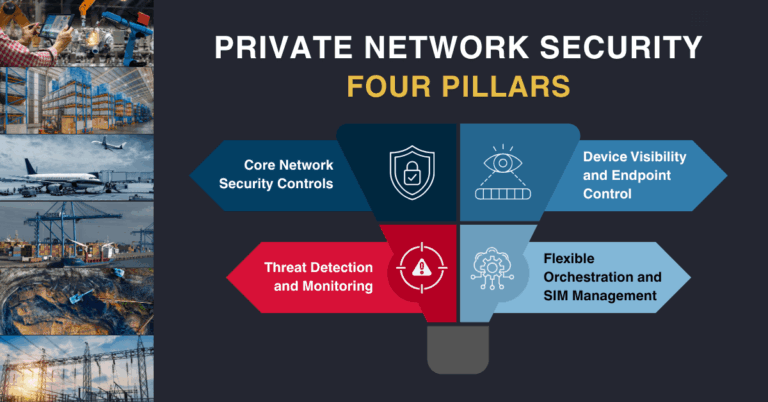

4) How mature is IT/OT integration, and how does private 5G close the gaps?

Traditional industrial automation leans heavily on wired Ethernet: reliable, secure, and ultra-low latency. But Ethernet comes with hard physical limits — once machines are cabled in place, reconfiguring layouts or adding mobile robots gets costly and slow.

Wi-Fi helps but quickly reaches its limits for high-mobility or high-density environments.

Private 5G directly addresses this:

- Mobility: Supports robots, AGVs, and reconfigurable lines.

- Predictable performance: Less prone to interference than Wi-Fi in metal-heavy factories.

- Edge computing integration: Real-time data stays local but syncs to cloud when needed.

- IT-OT convergence: Unified wireless layer connects sensors, PLCs, and MES.

Eric summed it up best:

“Today’s factories need flexible layouts, real-time video, and AI inference. Private 5G ties that all together without costly re-cabling.”

5) How is Korea tackling spectrum challenges, and which deployment models work best?

Globally, spectrum access is a major roadblock for industrial 5G. Korea tackled this head-on:

-

4.7 GHz band: Reserved for industrial and campus use, ensuring no competition from public mobile traffic.

-

Policy inspired by global leaders: Germany’s local licenses, Japan’s reserved factory bands.

-

Practical approach: Mid-band for balance — good indoor coverage and enough capacity.

Eric also gave a cautionary tale:

“We pioneered mmWave. It wowed the world at the Olympics. But we didn’t build on that. No commercial mmWave service exists today. So, spectrum policy must be matched with real incentives and support for industry rollouts.”

Deployment Models:

- Standalone private networks (SA): Fully owned, high security, zero reliance on public cores.

- Managed services: Operators deliver a turnkey 5G campus network for factories that don’t want ownership headaches.

- Open RAN and virtualized RAN: Reduce costs, break vendor lock-in, and enable more local integrators.

6) How are Korean manufacturers budgeting for private 5G and planning ROI?

Cost remains the #1 barrier. Wi-Fi’s low price point sets expectations unrealistically low for new industrial wireless tech.

Factories weigh:

- How quickly can they recover costs through productivity gains?

- Will automation cut enough labor costs to offset 5G infrastructure expenses?

- What’s the lifecycle cost vs. sticking with Wi-Fi and wired Ethernet?

To address this, more solution providers offer Network-as-a-Service (NaaS):

- No giant upfront CAPEX.

- Monthly or quarterly fees covering hardware, software, and support.

- Easier for CFOs to approve than big capital requests.

Eric was blunt:

“If private 5G is expensive and hard to operate, factories won’t adopt. ROI must be clear, and running the network must feel as easy as running Wi-Fi.”

7) What will it take to scale private 5G across Korea’s factories over the next 5 years?

Eric outlined two megatrends:

Virtualization:

The days of vendor-locked, hardware-bound baseband units are ending.

Modern base stations run as software on generic servers (vRAN). This lowers costs and opens the door for startups, universities, or local system integrators to develop and customize networks.

“In the past, only big companies could build base stations. Now, with software-defined radios, anyone can contribute.”

AI-native Networks:

Eric’s European projects, like 6G AROW, focus on rethinking the entire 5G/6G core to handle massive machine learning workloads, real-time LLMs, and robotic control loops.

Future private networks won’t just connect machines — they’ll co-manage edge AI, orchestrate dynamic slices, and automatically adapt to factory conditions with zero human input.

“I live every day in two time zones: one is today’s 5G reality, the other is 6G five years ahead. We must bridge both.”