Celanese Corporation, a global specialty materials and chemical leader, has deployed NTT DATA’s Private 5G network across two manufacturing sites in Texas. This rollout marks a major milestone in Celanese’s journey toward Industry 4.0, bringing secure, real-time connectivity to the edge of operations. The deployment enhances automation, safety, and decision-making, transforming traditional industrial processes with modern wireless infrastructure.

Overcoming Wireless Challenges in Industrial Manufacturing

Manufacturing environments like Celanese’s involve high-value processes that demand constant uptime and precise coordination. Yet, traditional wireless networks often struggle with signal interference, latency, and coverage limitations — especially in facilities with heavy machinery, metal structures, and mobile assets. Gaps in connectivity can lead to operational disruptions, data silos, and safety risks for frontline workers.

How NTT DATA’s Private 5G Enables Smart Factory Operations

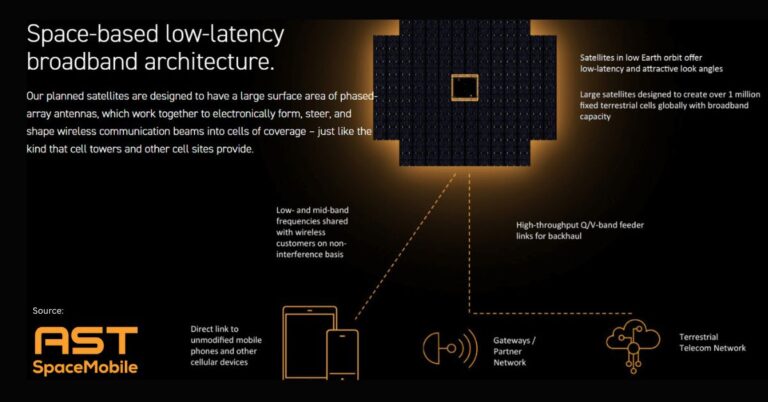

NTT DATA delivered a fully managed Private 5G solution designed specifically for industrial environments. The network provides ultra-reliable, high-speed wireless connectivity tailored for complex manufacturing operations. With seamless integration into Celanese’s digital ecosystem, the service enables real-time insights, secure communications, and automation at the Edge.

The deployment spans two key Celanese facilities — Clear Lake and Bishop, Texas — and is part of a broader strategy to digitize operations across the enterprise.

Real-World Use Cases of 5G in Celanese Facilities

With the new Private 5G network in place, Celanese is already exploring multiple edge-enabled use cases:

- Automation: Robots, sensors, and smart equipment can now connect securely and operate with low latency. This supports production line optimization and predictive maintenance strategies.

- Worker Safety: Real-time communication tools replace legacy radio systems, improving response times and situational awareness on the factory floor.

- Data Access at the Edge: Employees can retrieve critical data and instructions directly from the shop floor, enabling faster decisions and reducing manual steps.

- Operational Visibility: Enhanced connectivity enables end-to-end monitoring of logistics and materials flow — a key enabler for agile manufacturing.

Why Celanese Chose NTT DATA’s Fully Managed 5G Platform

NTT DATA’s Private 5G platform is a fully managed, enterprise-grade solution. Since its global debut in 2021, it has been recognized for scalability, security, and seamless cloud integration. Its ability to support Edge Computing makes it ideal for industries transitioning toward intelligent operations.

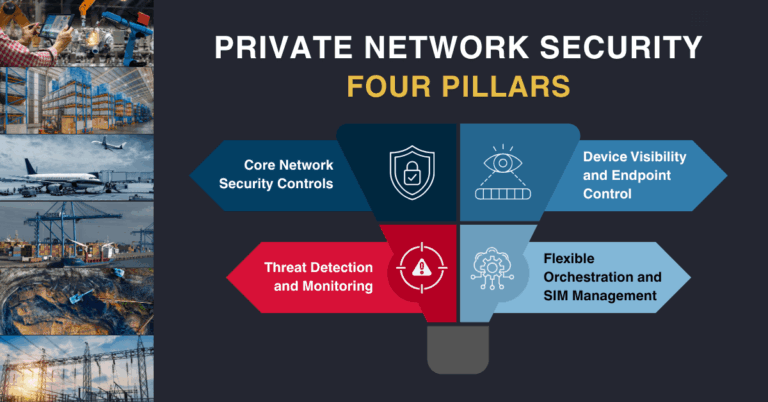

Benefits of Private 5G in High-Value Manufacturing Environments

- Reliability: Eliminates signal interference common in traditional networks.

- Security: Protects sensitive data through a dedicated, closed-loop system.

- Efficiency: Increases throughput and reduces downtime with real-time process visibility.

- Scalability: Ready to support future smart manufacturing use cases such as AI-based quality inspection and autonomous material handling.

What Celanese’s Private 5G Deployment Means for Industry 4.0

This deployment highlights how Private Networks are driving measurable results in the manufacturing sector. As more enterprises look to digitize operations, Celanese serves as a clear example of how 5G can modernize legacy infrastructure and enable a shift toward Industry 4.0. The integration of real-time communications, automation, and operational analytics at the edge creates a foundation for innovation in materials and process industries.

NTT DATA’s Role in Building the Future of Industrial Connectivity

NTT DATA brought its global experience in digital infrastructure and network transformation to deliver a turnkey Private 5G solution. Its offering includes deployment, management, and optimization — ensuring minimal overhead for Celanese’s internal teams. As a pioneer in enterprise 5G, NTT DATA continues to enable scalable solutions for forward-thinking manufacturers.

Celanese as a Digital Transformation Leader in Chemical Manufacturing

Celanese, as an early adopter, provided the environment, operational insight, and leadership to apply private 5G meaningfully. The rollout reflects the company’s commitment to digital excellence, worker safety, and sustainable growth.

Celanese’s Private 5G Network Now Fully Operational in Texas

The Private 5G network is now active in both Clear Lake and Bishop, Texas, manufacturing sites. Future expansions are likely as Celanese builds on this foundation to explore AI, robotics, and enhanced process automation.

- 2021: NTT DATA launched the world’s first enterprise Private 5G platform.

- Mid-2025: Planning and deployment began across Celanese’s selected facilities.

- September 2025: Official announcement of the live Private 5G network and operational readiness.

What Industry Leaders Say About 5G and Manufacturing Innovation

“We are proud to partner with Celanese as they navigate the complexities of modern manufacturing with a clear focus on innovation and operational excellence,” said Prasoon Saxena, Global President and Co-Lead, Products Industries, NTT DATA, Inc. “By deploying Private 5G services, they’re unlocking secure, high-speed connectivity that supports automation, enhances worker safety and enables real-time decision-making. It’s a foundational step toward building more agile, intelligent and resilient operations, and we’re proud to support them in that journey.”

“Our collaboration with NTT DATA strengthens our ability to implement advanced connectivity solutions, enhancing responsiveness, safety and efficiency for frontline teams,” said Sameer Purao, Senior Vice President and Chief Information Officer, Celanese.