Inside BMW’s AI-Controlled EV Plant Powered by Private 5G

BMW has opened the world’s first AI-controlled automotive factory in Debrecen, Hungary. This next-generation plant is where artificial intelligence, automation, and private 5G converge to power the production of electric vehicles (EVs). It’s also one of the most sustainable factories in the industry, relying entirely on renewable energy and zero fossil fuels.

With over 1,000 robots, autonomous vehicles, and real-time quality control powered by AI and edge computing, the Debrecen plant is a blueprint for the automotive industry’s digital transformation.

Connectivity and Automation Challenges in Building a Smart EV Plant

BMW faced several challenges while designing its newest plant:

- Scaling automation while maintaining flexibility in production

- Managing a high volume of connected devices across indoor and outdoor areas

- Supporting real-time AI-driven workflows and digital twins

- Ensuring low-latency, high-reliability connectivity for autonomous robots and worker devices

- Achieving carbon neutrality without sacrificing efficiency

Legacy wireless systems couldn’t deliver the performance and scalability needed for this kind of intelligent manufacturing environment.

How BMW’s Hybrid 5G Network Powers Intelligent Manufacturing

To meet these needs, BMW deployed a hybrid public-private 5G network across the Debrecen campus. Operated by Magyar Telekom, this network spans both indoor and outdoor areas—covering over 400 hectares, with about 15% of the area being indoor production space.

The network supports thousands of endpoints:

- Tablets and wearables for workers

- Industrial sensors

- HD cameras for real-time analytics

- Autonomous mobile robots (AMRs)

- AIQX-powered quality control systems

The combination of 5G and AI gives BMW the control, speed, and data fidelity required to run a fully automated, fossil-fuel-free facility.

Real-World Examples: AIQX, Digital Twins, and Autonomous Robots in Action

BMW’s Debrecen plant integrates several cutting-edge technologies:

- AIQX system: A fusion of AI, sensors, and cameras, this system detects quality issues like paint defects or component alignment errors in real time.

- Digital twins: Every production robot was virtually simulated before real-world deployment, streamlining automation design.

- Autonomous transport: AMRs navigate the campus, guided by private 5G connectivity and real-time data.

- Renewable energy: The plant operates entirely on electricity from renewable sources, with no fossil fuel usage at any stage of production.

- Next-gen battery production: The plant will produce Gen6 high-voltage batteries locally, reducing emissions from transportation and aligning with BMW’s “local for local” sustainability strategy.

BMW’s 5G and AI Architecture at the Debrecen EV Factory

BMW selected a hybrid 5G network architecture:

- On-premises RAN for low-latency, localized communication

- Private 5G core for secure, role-based traffic segmentation

- Integration with AI workflows at the edge

- AI and machine learning tools for predictive maintenance and process optimization

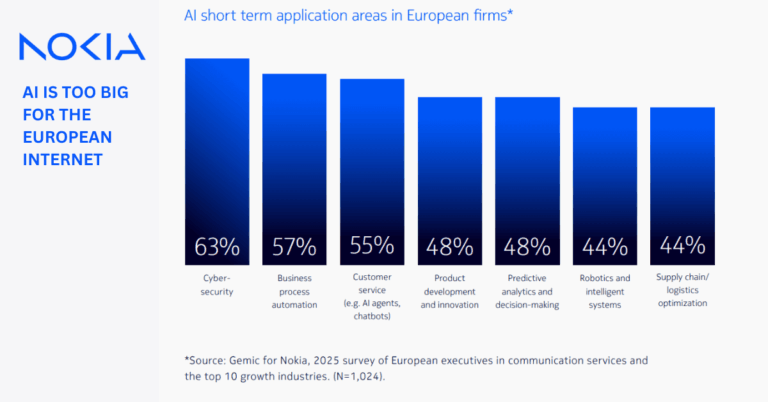

The company has previously worked with vendors like Celona and Nokia for private network testbeds, although the specific RAN vendor for Debrecen remains unconfirmed.

Key Benefits: Efficiency, Quality, and Sustainability with Private 5G

The implementation of private 5G and AI offers several advantages:

- Real-time automation: Instant feedback loops via sensors and cameras improve efficiency and reduce defects.

- Improved quality control: AI detects micro-errors before they impact production timelines.

- Energy efficiency: Electrified processes reduce CO₂ emissions by up to 90%.

- Flexible manufacturing: Digital twins enable fast reconfiguration for new vehicle models.

- Sustainability: The factory is entirely fossil-fuel-free and runs on 100% renewable energy.

How BMW’s Debrecen Model is Shaping Smart Automotive Factories

BMW is setting a precedent for other automakers. It’s not just about EVs—this is about creating data-first factories powered by AI, automation, and private networks.

Other automakers like Tesla, Porsche, and others are also pursuing 5G private networking, but BMW is taking a multi-site approach. Besides Debrecen, BMW has private 5G deployments in:

- Spartanburg (USA)

- Dingolfing (Germany)

- Leipzig (Germany)

- Landshut (Germany)

- Shenyang (China)

This cross-site consistency helps BMW scale innovation while maintaining quality.

BMW’s iFactory Vision: Digital-First, Zero-Fossil EV Manufacturing

BMW Group has embraced a digital-first philosophy across its global operations. Debrecen is a key pillar of the company’s “iFactory” strategy, which emphasizes:

- Digitalization

- Sustainability

- Flexible production

BMW’s investment also supports regional job growth, local supply chain development, and university partnerships for AI and robotics training.

Magyar Telekom, Nokia, and Academia: Supporting BMW’s Tech Stack

- Magyar Telekom: Delivered and operates the hybrid 5G network on-site, ensuring secure, reliable connectivity across the campus.

- Celona and Nokia: Previously supported BMW’s private 5G testbeds, offering a foundation for future deployments.

- University and training institutes: Help train the next generation of engineers and robotics experts, further integrating the plant into Hungary’s innovation ecosystem.

Timeline: BMW Debrecen’s EV Production and 5G Deployment Milestones

- Facility is live as of Q4 2025

- Production of the new iX3 EV begins October 2025

- Local battery production begins in tandem, supporting BMW’s next-gen EV roadmap

- The Debrecen plant is the first of five global sites set to produce Gen6 batteries

- 2022–2023: Factory design using digital twin technology

- 2024: Construction and hybrid 5G network deployment

- Mid-2025: Testing and integration of robots, AI systems, and autonomous logistics

- October 2025: iX3 production starts

- 2026: Scale-up of battery production and expanded AI use cases